Track Package

Method for constructing paved concrete track by using high-flowablity and high-early-strength mortar

- Inventors :

- Korean Railroad Technology Institute, Hwasung Railroad Co., Ltd, and SsangYong

Cement (Chunwun Railroad Co., Ltd is a subsidiary of Hwasung Railroad Co., Ltd)

- Address :

- 374-1, Wolam-dong, Uiwang-si, Gyunggi-do

- Protection period :

- 2009. 04. 07 ~ 2012. 04. 06 (3 years)

Description of the new technology

Brief description

- The present technology relates to a method for using mortar that has characteristics including high flowability, recyclability, and high-early-strength (Bacon-MF).

- The present technology relates to a method for constructing paved concrete track by suing Bacon-MF.

- The present technology relates to a method for reconstructing track by process of making concrete slab for a purpose of track maintenance within limited working time. The process involves in eliminating ballast track; reconstructing track panel using nonwoven cloth and cleaned ballast; and pouring concrete mortar. The process does not take much time, thereby can avoid interfering train operation.

Principle and Construction Method

Principle

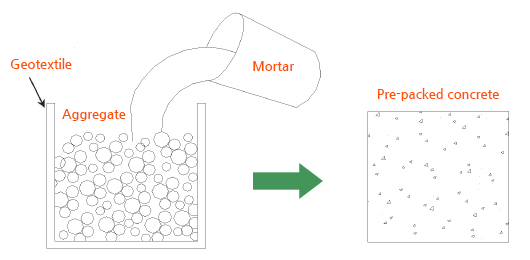

[ Concept of pouring mortar for paved concrete track ]

[ Concept of pouring mortar for paved concrete track ]

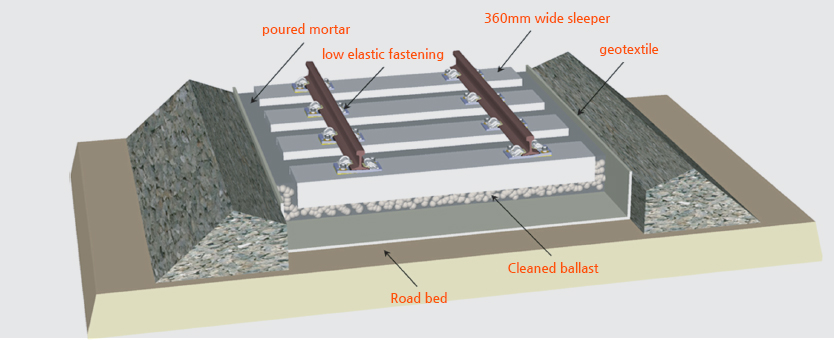

- The method is an application of a pre-packed concrete technique, which involves in making concrete slab by filling layers of ballast with Bacon-MF. Wide sleeper, low elastic fastening, geotextile, and cleaned ballast are used for paved concrete track. The method makes the construction process simple. Thus, maximum 30 meters of track structure can be reconstructed within 3-4 hours, which can avoid interfering train operation.

Construction method

- The method for constructing paved concrete track, comprising : replacing old ballast and track panel with cleaned ballast and wide sleeper; pouring mortar to fill layers of aggregate wrapped by nonwoven cloth to prevent irregularity of track; using wide sleeper to decentralize ballast pressure; and using adjustable fastening for making maintenance easy. The whole process can be completed during non-traffic hours (2-3 hours per day). The unique feature of the method is recycling old ballast by using dry-washing technology that has been developed for the first time in the world.

[ Conceptual Diagram ]

[ Conceptual Diagram ]

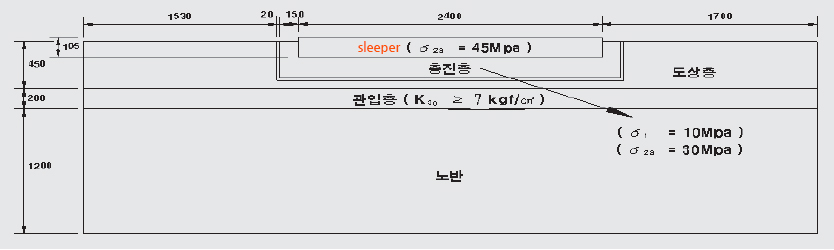

[ Roadway digraph for paved concrete track ]

[ Roadway digraph for paved concrete track ]

Use of the new technology

Applied construction Projects

| Testing construction for track system development | |||

|---|---|---|---|

| Construction Period | 2007.11.21 ~ 2007.12.20 | Construction Cost | 95,000,000 |

| Organization | Seoul Metro | Department | Railroad & Civil Team |

| Content | Testing construction for performance evaluation for Seoul Metro Line 1 between Seoul and Namyoung station | ||

| Testing construction for track system development | |||

|---|---|---|---|

| Construction period | 2007.5.29 ~ 2007.5.30 | Construction Cost | 31,000,000 |

| Organization | Busan Transportation Corporation | Department | Civil Team |

| Content | Testing construction for processing method for paved track | ||

| Construction for third rail | |||

|---|---|---|---|

| Construction period | 2009. 4 .15 ~ 2009. 7 14 | Construction Cost | 498,000,000 |

| Organization | Korea Rail Network Authority | Department | Track Structure R&D Team |

| Content | Paved track construction for constructing third rail (410m) | ||

Applicable areas

- For more efficient maintenance for old ballast track

- For difficult sections for reconstructing track structure such as bridge concrete track or nose turnout

- For sections that are difficult to have long working hours for maintenance

Technological and economical effects

Technological effects

- Obtaining own technological capability for reconstructing ballast track of tunnel section and urban railroad

- Promoting use of the new technology for various types of tracks by designation as a new technology by the government.

- Obtaining technological grounds to expand domestic/overseas track reconstruction markets through making the new method for Korean model of paved practical

- Immediately applicable for current or planned projects for reconstructing old ballast track of urban railroad

Economical effects

- Additional source of increasing revenue expanding track reconstruction market

- Construction cost for paved concrete track : 1,400,000,000 KRW/km

- Current status of old ballast tracks in Korea : urban railroads (370km), general railroad (1,000km)

- Reconstruction of 200km : earning of 280,000,000,000 KRW

TOP

TOP