AGT Track

Method for constructing a railroad by using a guideway for a rubber-wheeled automated guideway transit system

- Inventors :

- Korea Railroad Technology Institute, Hwasung Railroad Co., Ltd

(Chunwun Railroad Co., Ltd is a subsidiary of Hwasung Railroad Co., Ltd)

- Address :

- 374-1, Wolam-dong, Uiwang-si, Gyunggi-do (Tel. 031-460-5326)

482-33, Yachonri, Gayagok-myeon, Nonsan-si, Choongchungnam-do (Tel. 041-742-5037)

- Protection period :

- 2013. ○1.○○ ~ 20○○. ○○. ○○ (○ years)

Description of the new transport technology

Brief description

- The present technology relates to a method for constructing a railroad for a rubber-wheeled automated guideway transit (AGT) system by using lateral guideway preinstalled by using a guideway-assembling device.

- The present technology relates to a method for constructing a railroad for a rubber-wheeled automated guideway transit system by installing and using a guideway with predetermined plane curve radius, amount of cross gradients, and transition curves before constructing a driveway, which results in minimizing construction costs and maximizing construction efficiency by eliminating post processes such as a grinding process and the like and improving construction precision by using the guideway as a standard to construct a railroad that linearly varies.

Principle and Construction Method

Principle

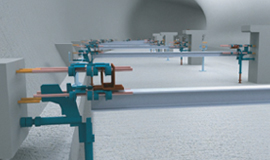

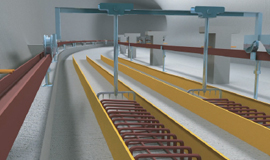

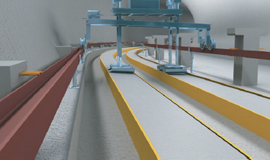

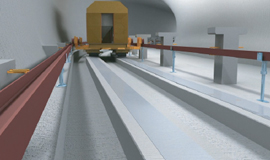

- Acknowledging that a guideway and a driveway are aligned each other, a railroad should have the same trace as the guideway in terms of horizontal alignment, longitudinal alignment, and amount of cross gradients. The railroad is constructed by moving a finisher along the guideway to form top surface of a concrete driveway based on predetermined horizontal alignment, longitudinal alignment, amount of cross gradients of the preinstalled guideway.

Construction method

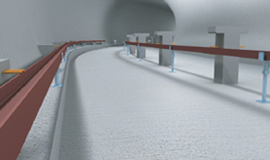

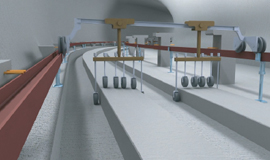

- The method for constructing a railroad for a rubber-wheeled AGT system, comprising; installing guideway assembling devices; constructing a guideway after measuring the horizontal alignment and amount of cross gradients by using the guideway assembling device; arranging steel bars at a precise place where the railroad will be formed; installing molds around the arranged steel bars; pouring concrete into the molds; forming 소 driveway by moving a finisher along the guideway to form top surface of the concrete driveway in accordance with the guideway; measuring flatness test after the concrete is flattened; and polishing the concrete based on the flatness data.

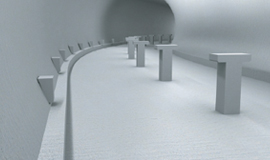

Tunnel

Tunnel Installing guideway assembling device

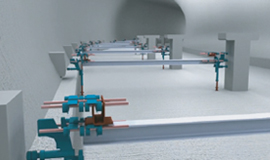

Installing guideway assembling device Measuring horizontal alignment and amount of cross gradients

Measuring horizontal alignment and amount of cross gradients Attaching scaffold & burying bolts

Attaching scaffold & burying bolts Constucting guideway

Constucting guideway Arranging steel bars and installing molds

Arranging steel bars and installing molds Forming concrete driveway

Forming concrete driveway Measuring flatness test

Measuring flatness test Polishing surface of concrete driveway

Polishing surface of concrete driveway

Use of the new transport technology

Applied construction projects

- This method has been developed since 2008 and applied to the below construction projects, resulting in reducing construction costs and maximizing construction efficiency by shortening construction period and improving construction precision. Currently, Busan Subway Line 3 is successfully being operated.

| Project | Construction cost | Contractor | Construction Period |

|---|---|---|---|

| Railroad 2nd stage construction & Pillar installation on Busan Subway Line 3, Section 333 | 1,450,000,000 | Daelim Corporation | 2009.8~2011.3 |

| Railroad 2nd stage construction & escape way pillar installation on Busan Subway Line 3, Section 322 | 730,000,000 | Daewoo E&C | 2009.8~2011.3 |

| Railroad 2nd stage construction on Busan Subway Line 3, Section 4 | 450,000,000 | Samwhan Corporation | 2009.8~2011.3 |

| Railroad 2nd stage construction on Busan Subway Line 3, Section 4 | 110,000,000 | Hyeopsung Corporation | 2009.8~2011.3 |

Applicable areas and perspectives on application

- A rubber-wheeled AGT system is more capable for curves and steep gradients than a steel-wheeled AGT or magnetic levitation AGT. Thus line of railroad for a rubber-wheeled AGT system is shorter than other types of AGT system. Accordingly, a rubber-wheeled AGT system is often preferred as it reduces construction cost and attracts more passengers who live in curvy urban areas.

Currently, many local governments and railroad companies are strongly interested in adopting a driverless rubber-wheeled AGT system because it is economical and environmentally friendly compared to a conventional subway.

Currently, Seoul (Dongbook Line, Shinlim Line), Gwangmyeong LRT, Choongnam (1st & 2nd stage of Cheonan Line), Busan (Choeup Line between Sasang and Hadan) are considering adopting a rubber-wheeled AGT system. In this case, the present technology will be more practically applied

Technological and economical effects

Technological effects

- Obtaining technological independence and capability for constructing a rubber wheeled AGT system

- Capable to export the new method and apparatus for overseas railroad construction projects (d.g., a guideway assembling device, a concrete finisher, a flatness tester, and concrete surface polisher etc.)

- Applicable for railroad sections under the ground

- Increasing construction management efficiency by constructing a guideway and a driveway at the same time

Economical effects

- Reducing about 7% of construction period by constructing a guideway and a driveway at the same time

- Reducing construction cost, especially when installing molds and planarizing concrete driveway and by using a finisher riding on preinstalled lateral guideway

| Work | Apparatus | Amo unt | Unit | Old Method(a) | New Method(b) | Cost Difference(b-a) | ||

|---|---|---|---|---|---|---|---|---|

| Unit Price | Cost | Unit Price | Cost | |||||

| Driveway | 1 | km | -43,678,400 | |||||

| Forming concrete | Finisher+leveler | 2,300 | m² | 21,369 | 49,148,700 | 49,148,700 | ||

| Forming concrete | Machine | 2,300 | m² | 32,191 | 74,039,300 | -74,039,300 | ||

| Installing molds | Plywood (4 times of use) |

600 | m² | 28,973 | 17,383,800 | 17,383,800 | ||

| Installing molds | Steel molds | 600 | m² | 60,286 | 36,171,600 | -36,171,600 | ||

TOP

TOP