Research Result

New Technology

-

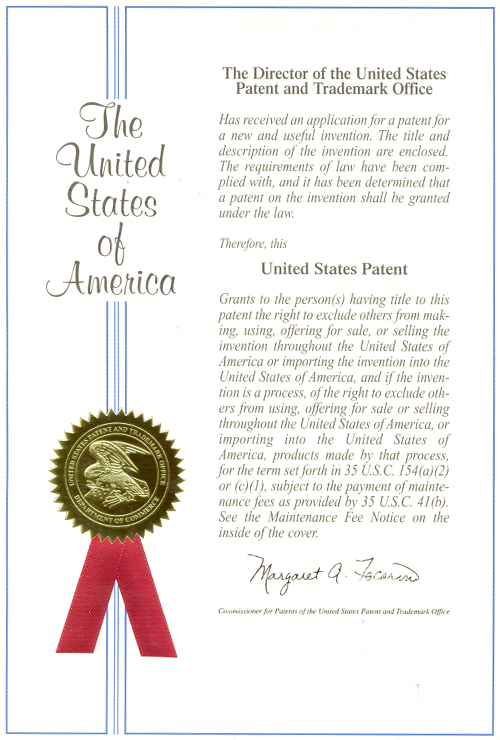

Rubber wheel AGT America Patent

Rubber wheel AGT America Patent -

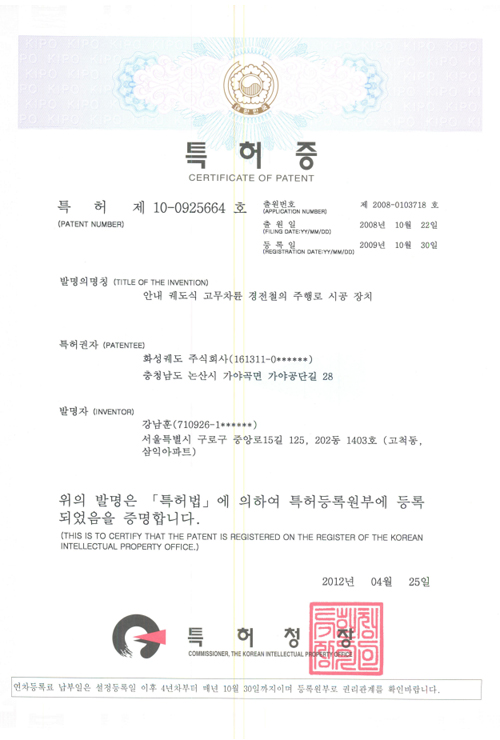

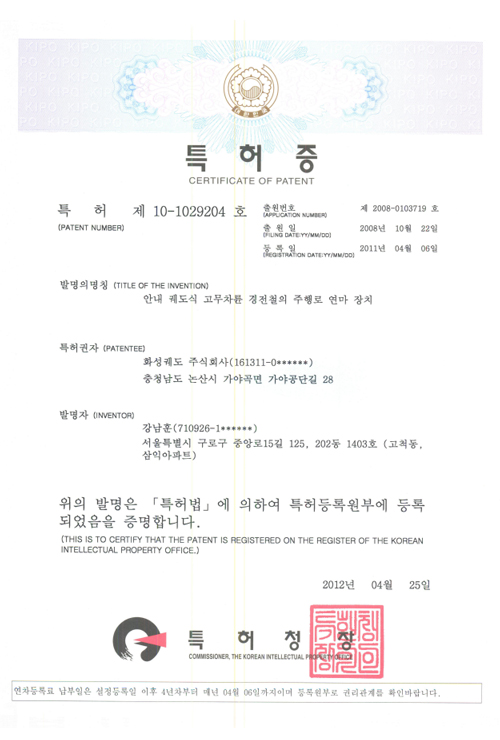

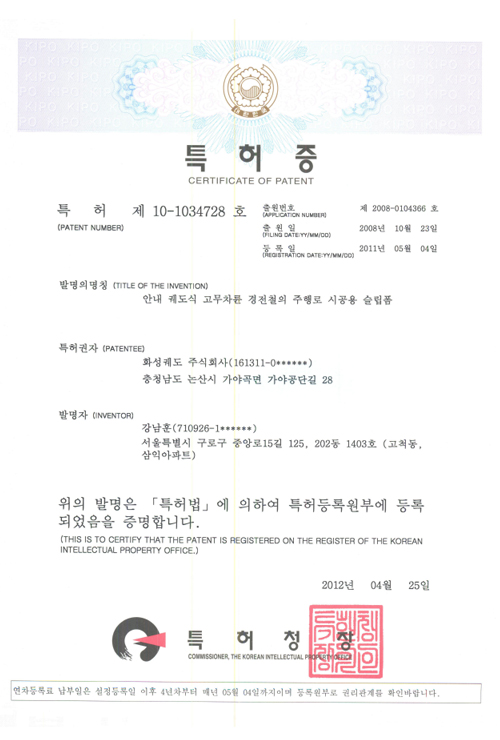

Rubber wheel AGT taking place in the onsite placement Patent

Rubber wheel AGT taking place in the onsite placement Patent -

Rubber wheel AGT taking place in the onsite placement Patent

Rubber wheel AGT taking place in the onsite placement Patent -

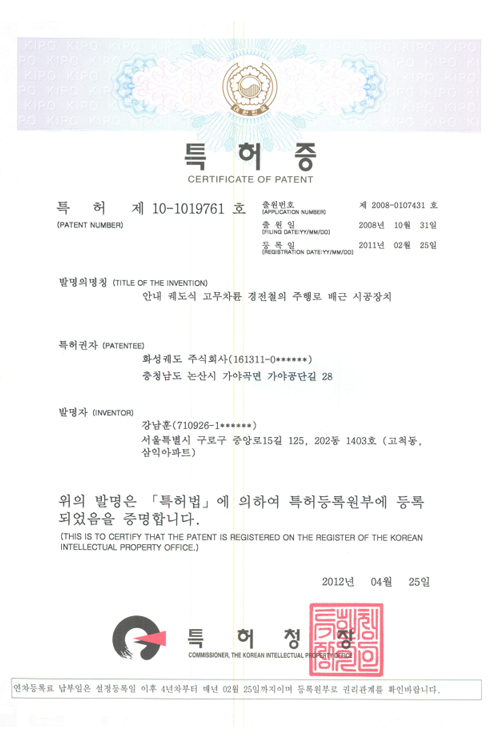

Rubber wheel AGT taking place in the onsite placement Patent

Rubber wheel AGT taking place in the onsite placement Patent -

Rubber wheel AGT taking place in the onsite placement Patent

Rubber wheel AGT taking place in the onsite placement Patent -

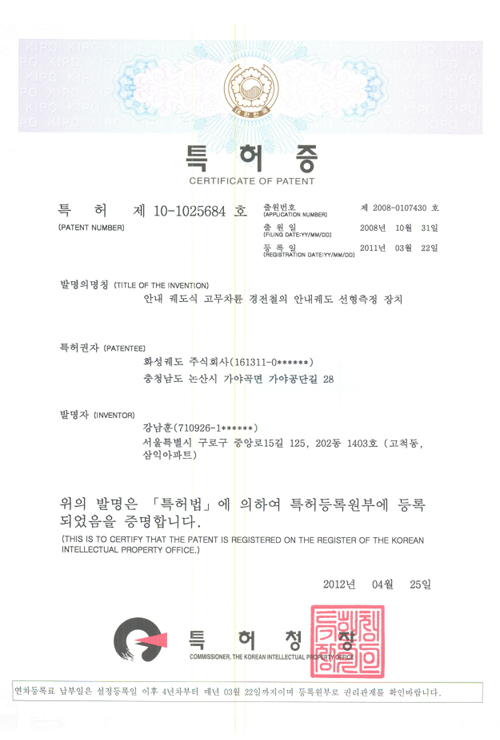

Rubber wheel AGT taking place in the onsite placement Patent

Rubber wheel AGT taking place in the onsite placement Patent

Patent

What is 3D-PST?

The 3D-PST technology has, as its matrix, the method of constructing the running rails using the guidance rails of the rubber wheel AGT’s, which received the designation as the number 14 of the new traffic technologies through the joint researches by the Hwasung Tracks and the Korea Railroad Research Institute.

This construction method is a technology which made the precise construction of the running rails, which are the cores of the running stability and the riding comfort of the AGT vehicles by constructing the running rails after advance constructing the guide rails which become the base lines of the construction.

Especially, this technology has been receiving the evaluation that it can gather the effect of reducing the construction costs according to the formal changes of the running rails by expanding the applicability of the separation-type running rails to throughout all the sections of the planned routs regarding the form of the running rails of the integral type and the separation type that had been differently applied according to the planned roadbeds, including the civil engineering, the bridges, the tunnels, etc. until now.

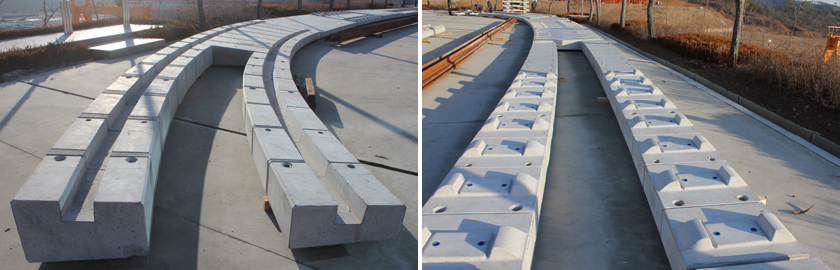

The 3D-PST technology that was born based on such a technology is produced by using the curves constructed on the site and by using the data through the linear accounts and the on-site measurements and is produced by using the factory-type track skeleton chassis of which the precise linear setting up is possible at the factory and the curved-form molds.

The track skeleton chassis can be produced until the minimum radius of curve of R=15m so that it can be applied to the rubber wheel AGT’s, trams, etc. And the cants can be produced until the maximum of 180mm for the production of the panels which can be applied to the high-speed railroads and the others of the like.

In the same way as the track skeleton chassis, the curved-type molds, also, can be produced until the minimum radius of the curve of R=15m. They have been organized so that the installation of a traverse mold, too, is possible by making the production possible with the free lengths of the panels according to the requirements of the site.

Meanwhile, regarding the most innovative thing in the production of the 3D-PST’s, the point of making the production of the panels that simultaneously possess the curves and the cants is important.

Through the development of the direction separation-type panels, the applicability to the underground sections and the others of the like were even more expanded. The point is that the production cost could be reduced by about 1/3 than the integral type.

The fields of application

The applicability of the 3D-PST is very extraordinary in the part of the general railroads, including the high-speed railroads, the subway, the light rails, etc.

Regarding the 3D-PST, its applicability is more extraordinary not only to the construction in the straight sections, but, also, as a matter of the special characteristics, the applicability to the sharp curves and the underground sections of the light rails to which the application of the precast panels has been either impossible or difficult until now is more extraordinary.

The precast slab panels that have been developed and used for the constructions at present in Korea and overseas have been applied mostly to those of which the minimum radiuses of the curves are R=800m or longer.

But, in case the rectangular form panels can be applied to the curved sections, many kinds of problems take place.

For example, in the case of setting up the planned curved lines in the rectangular form panels, the fastenings of the rails and the panels tighten in the right angle only if the fastening moves up and down, rotates from left to right, etc. according to the radius of the curve.

Also, when setting up a cant in the curve section, the shim plate must be tightened in the lower part of the fastening. And the packed bed that connects the floor concrete and the panels must be additionally constructed to the extent of the height of the cant and the others of the like. As such, the cumbersome tasks must be added.

Compared to this, the 3D-PST has added the curves and the cants on the panels, themselves. As such, the tracks that possess the planned lines (the curve radiuses) and the cants that were planned can be built by only descending the panels to the site and connecting the panels to each other without the many processes that were raised earlier.

Especially, through the research, the development of a longitudinal separation-type panel and the construction of the precast slab tracks of the underground sections were made possible. And the material costs and the construction costs, too, can reduce by 1/3 compared to the previously existent integral-type panels.

At present, the state is that the Korea Railroad Research Institute, at Nokjiseon, has completed the construction for the 3D-PST tests for the ordinary railroads.

The applicability of the 3D-PST is extraordinary in the field of the rubber wheel AGT field.

Regarding the rubber wheel AGT’s, ever since their first introduction on the Bansong Number 4 Line in Busan, the vehicles have presently been operated on two lines together with the Euijeongbu Light Rail.

Regarding the rubber-wheel AGT’s, because the precast slab panels have not yet been developed until now, the building has been taking place in the onsite placement method.

At present, in the case of the panels for the railroad use, the panels have been separated with the certain gaps of from 100mm to 200mm. As such, the task of offsetting the twisting of the panels in the curve sections to a certain range is possible by using these spaces. However, the wheels of the rubber-wheel AGT’s are the rubber wheels like cars. And the rubber-wheel AGT’s run on the exclusive tracks called the “runways”, which are the continuous supporters without the surfaces of the discontinuities.

Although the ordinary railroads set up the curved lines and the cants on the rails, the rubber-wheeled AGT’s set up the curved lines and the traverse slope amounts (cants) on the runway concretes, themselves. Or, in other words, as the concretes of the runways, themselves, play the role that is the same as the rails of the railroads, when producing the panels, the panels, themselves, must include the curved lines and the cants as required by the railroads.

As a result, Hwasung Tracks and the Korea Railroad Research Institute have developed the 3D-PST for use with the rubber-wheeled AGT’s. In the field of the rubber-wheeled AGT’s, too, which had been impossible until now, not only have the slab panel constructions become possible, but, also, the strengths of the concrete panels, too, became able to obtain the strength of 450Mpa, which is much more extraordinary than the 35Mpa, which is of the onsite placement method.

Also, in the case of using the separation-type panels for use with the rubber-wheeled AGT’s, the constructions with the precast slabs are possible in the underground sections. And, in the case of installing the sound absorbing materials and the others of the like by utilizing the central spaces of the separation-type panels, the effect of reducing the noises can be brought forth.

Other than these, in the case of changing the lateral guidance method of the present into the central guidance method by using the central parts of the separation-type panels, the reduction of the structures, including the civil engineering structures and the others of the like, is possible. In the future, the reduction of the construction costs can be achieved until the interface field. And the diverse changes of the system specifications can be pursued.

Regarding the development progress of the precast panels of the rubber wheel AGT’s at present, the examination of the panel structures is in the completed condition. The test construction was completed on the Gyeongsam Testing Line of the Korea Railroad Research Institute.

Meanwhile, the 3D-PST technology can applied to the burial track field, too, including the trams, the trolleys, etc.

The burial tracks are ordinarily very much utilized by the trams, the trolleys, etc. above ground. Generally, regarding the trams, they are used by having the cars and the trains go side by side on the tracks. And they pass the centers of the downtowns. For passing the crossroads and the intersections, the planned lines are materialized with the severe curves.

Most of the trams until now have been built in the site placement method. The shape in which a rail of the tram is buried gets formed by using the slip-form tape.

But, in case a tram is built using such a slip-form tape, the construction at a downtown area uses two lanes. Thereby, not only will the traffic congestion be caused within the downtown area, but, also, the time period of the construction increases because the time period of the curing of the concrete and the others of the like becomes considerably lengthy.

Also, in order to construct the burial tracks in the underground sections in the in-site method, the equipments, including the slip-form tapes and the others of the like must be inputted below ground. And, although there is a need to transfer the 4cm low-slump concretes to the underground sections, this has a considerable difficulty realistically.

Compared to this, in the case of utilizing the 3D-PST for the burial tracks, when carrying out a construction in the downtown area, the production shall be made into the precasts prior hand at the factory. And, after carrying out the bed excavation construction for only the parts needed at the site, if you only install the panels, the construction can be completed. As such, because of this, the time period of the construction can be shortened. And, as the space of the work captures only 1 lane, the induction of the traffic congestion can be reduced.

Also, when applying to the underground sections, too, the separation-type panels can be used. And by adding the curve radiuses and the cants prior hand, after producing the panels, if the panels are inputted, carried, and installed in the underground sections, as the construction of the burial tracks is possible, it is forecast that, in the future, the usabilities will be extraordinary regarding the low-depth railroads and the others of the like.

Regarding the current burial tracks, too, at the Korea Railroad Research Institute has implemented the test construction and has been proceeding with the performance tests at Nokjiseon.

The expected effects

The 3D-PST is a technology that was developed for the first time in the world. By securing the original technology, it is forecast that it will become an opportunity for increasing the technological exports and for heightening even more the status of the Korean railroad technologies in the world market.

Especially, to the extent that it has been receiving the evaluation as a technology that draws an innovative stroke in the railroad tracks field, which had relied only on the imports without the self-owned technologies in the Korean railroad industry until now, it is forecast that there will be the great contributions to the import substitution effects and the technological developments of Korea. And, also, when applying to the shallow-depth railroad field, like the Number 2 Line of the Gwangju Metropolitan Railroad, of which the ordering is schedule for the future, it is forecast that the economic and the social effects, including the construction costs, the work efficiencies, etc., will be considerable.

Video

3D PST test construction

| Rubber tired AGT detachable panel process video | View ⇒ |

|---|---|

| Flush orbit detachable panel process video | View ⇒ |

| Railway curved detachable panel process video | View ⇒ |

| Rubber tired AGT detachable curved panels designed and tested construction | View ⇒ |

| Rubber tired AGT situ technique Video 1 | View ⇒ |

| Rubber tired AGT situ method Method 2 video | View ⇒ |

| Placing a rubber tired AGT construction-related video site | View ⇒ |

| Earthwork interval, bridges and underground section poles rail transport truck | View ⇒ |

| Common Rail and Metro section of concrete poured directly process | View ⇒ |

| General Railroad and subway concrete pouring process conducted directly Ball Video | View ⇒ |

| General railway station at night off the line work directly casting process conducted Ball Video | View ⇒ |

TOP

TOP